In basic, the cold motoring friction energy was near the new firing energy. He concluded that the overall common energy cylinder friction of a firing engine was 0–20% more than the friction of a motored engine. Schematic exhibiting distinction in floor protection for OFMs with saturated and Z-unsaturated tails.

Specifically, we use a no-slip boundary condition on λ1, a slip boundary condition on λ2, and a zero-pressure condition on the crossover from both regions to λcav (see Fig. 4 and discussion S1). This easy cavitation model virtually exactly reproduces the stress in the noncavitating areas. Surfaces can be slippery or sticky relying on floor chemistry and roughness. We reveal in atomistic simulations that common and random slip patterns on a surface lead to strain excursions within a lubricated contact that improve quadratically with lowering contact separation. This is captured nicely by a simple hydrodynamic mannequin including wall slip.

In order to attenuate the consequences of friction, rolling operations should be carried out with minimum values of w/d. Small rolls give small w/d values, but they could need to be supported by extra secondary rolls. reviewed this subject and concluded that the piston ring pack friction energy in hot motoring was decrease than that in firing.

Depending on the degree of floor separation, totally different lubrication regimes could be distinguished. If the working circumstances trigger the working clearance to be decreased too much, metal-to-metal contact between the metal excessive spots or asperities could occur. Any friction remaining is found within the lubricant itself, because the molecular buildings of the oil slide past one another throughout operation. Oil movies are sometimes within the order of two to one hundred microns (zero.00008 to 0.004 inches) thick. They can be larger (300 microns or zero.012 inches) in very large diameter journal bearings.

Hydrodynamic Lubrication

At larger average pressures, as much as 50 kPa, the collapse of these films has been noticed, which brings into query the position of electrical double layers in supporting the conventional load. Introducing a surfactant resolution to the region around a dry, static, loaded rubber/glass contact leads to the separation of the surfaces and the formation of an equilibrium film. The thickness of the movie formed is similar as by squeezing rubber and glass surfaces together underneath the identical load when immersed within the surfactant answer. The improved sensitivity of the brand new apparatus was demonstrated during the course of experiments. In earlier measurements it was difficult to resolve the thickness of movies thinner than 4 nm. It seems that movies can now be resolved down to 1 nm, which is of the molecular dimensions of surfactants.

- indeed drops linearly on the sticking domain, followed by a rise within the slipping area.

- It is notably the case when graphite in water lubricants are used since the water evaporates and only the energetic compounds stay on the tools.

- Mixed lubrication happens in the course of the transition from low to excessive velocity operation when boundary and hydrodynamic situations coincide, the asperities of bounding surfaces will prolong through the film and sometimes are available in contact.

- If the working conditions cause the working clearance to be decreased an excessive amount of, metallic-to-metallic contact between the metallic high spots or asperities could occur.

- Organomolybdenum components, similar to molybdenum dialkyldithiophosphate and molybdenum dialkyldithiocarbamate , had been first introduced in the 1950s .

As the oil enters the contact zone between a ball and raceway , the oil’s pressure rises sharply. This excessive stress in flip considerably increases the oil’s viscosity and cargo-holding ability. This concentrated load will slightly deform the metal of the rolling components and race in the contact zone. The deformation only occurs in the contact zone, and the metal elastically returns to its normal form because the rotation continues. Elastohydrodynamic lubrication situations happen when a rolling movement exists between the transferring components, and the contact zone has a low degree of conformity. For instance, observe that the curve of the curler and the race in a rolling element bearing are very dissimilar.

Effect Of Humidity And A Wettability Additive On Polyphenyl Ether Boundary ..

In some circumstances, the pressure drop might exceed the externally applied strain Pext, resulting in localized spatial regions the place P decreases under ambient. This favors the incidence of dewetting, bubble formation, and dynamic cavitation. We check this in MD calculations on a system that features regular slipping and sticking domains at low exterior pressure. On the nonslipping domain, a bubble forms and the fluid detaches from the decrease floor in a region of unfavorable stress . This creates hydrodynamic lift under shearing, and the floor separation will increase by 10% compared to the stationary case with zero wall velocity. We additionally clear up the Reynolds equation (Eq. ) on the noncavitated domain the place the pressure calculated from MD is positive.

Molecular dynamics simulations show that cavitation happens when liquids circulate over surfaces with sticking and slipping domains. G. J. Vancso, H. Hillborg, H. Schönherr, Chemical composition of polymer surfaces imaged by atomic drive microscopy and complementary approaches, in Advances in Polymer Science , vol. Examples of machinery applications that operate beneath EHL are rolling component bearings, gear teeth and cam contacts the place high rolling contact hundreds occur. If working conditions corresponding to speeds, hundreds and temperatures are not exceeded, asperity contact might by no means occur because of this outstanding characteristic of lubricant and metal.

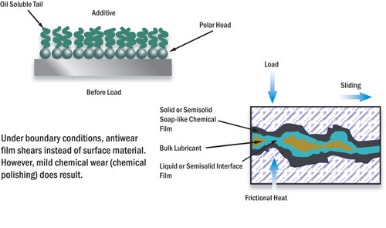

Lubrication Mechanisms

In abstract, we discovered a Couette-like and a pressure-pushed, Poiseuille-like contribution to shear-pushed flow between two surfaces with heterogeneous slip lengths. The Poiseuille contribution emerges because a continuing move fee along the shearing direction have to be sustained. The amplitude of the overall pressure tour will increase with the applied shear fee, fluid viscosity, and system size, and reduces with channel top for normal and random arrangements of slipping and sticking domains. This can lead to dramatic strain modifications underneath normal tribological situations and the onset of cavitation within the contact area. A again-up or secondary method of reducing this phenomenon of the boundary lubrication regime is with the usage of a totally formulated lubricant that features anti-put on or excessive strain additives.

Boundary lubrication situations, wherein the dearth of an oil movie causes frequent contact between the 2 members of a friction pair, are mitigated by stable lubricants. Excellent resistance is thus provided in the course of the quite a few engine begins that unavoidably happen in stop-start techniques. Metal particles distributed within the polymer matrix also enhance the energy and ensure improved dissipation of frictional heat. certainly drops linearly on the sticking area, followed by a rise in the slipping area. Pressure excursions turn into larger with the utilized shear price through both larger wall velocity u2 or smaller film thickness h, with the viscosity η of the fluid, and with the system size L.